KEEP THE BEEP:

GT Capstone Project

PROBLEM

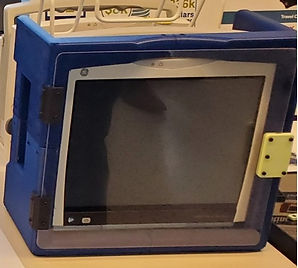

Emory University Hospital relies on the GE Carescape B450 physiological monitor, however it is frequently damaged during high-pressure patient transport due to rough handling and loose mounting on hospital beds.

SOLUTION

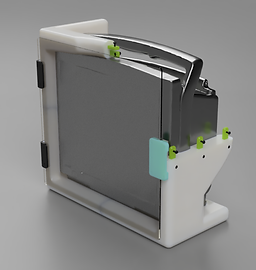

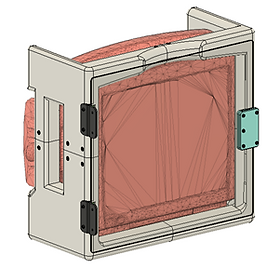

Create a soft protective housing which is designed for manufacture and tested for use in Emory Hospital Midtown. The case must protect all monitor regions from impact, be chemically inert, and easily sanitized.

PROJECT VIDEO

Major contributions...

Used FaroArm Quantum 3D Scanner and 3D printing to enable rapid design and prototyping

Used 3D scanner to quickly import geometry into SolidWorks CAD and Fusion360, allowing for fast and accurate modeling of a case which fits the monitor. Design was then 3D printed using soft TPU filament for the case body and PLA for connecting pieces.

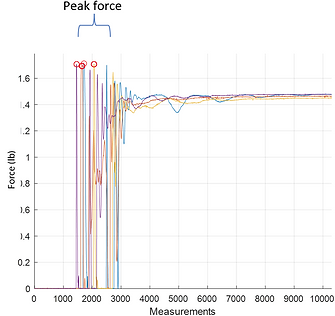

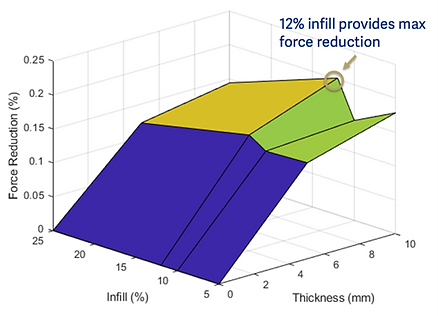

Conducted impact analysis to optimize design parameters

Design parameters such as thickness and infill were varied and then tested for impact reduction using custom designed. Testing apparatus was created using a parallel configuration of strain gauge pads and Adafruit Metro M4 microcontroller.

Led the prototype manufacturing and prototyping. Design is modular, chemically inert, completely recyclable or down-cyclable, and highly impact resistant

Hardware is nylon, soft body parts are made of TPU, interior connectors are PLA plastic, the front door cover is polycarbonate, and the front lock is a neodymium magnet.

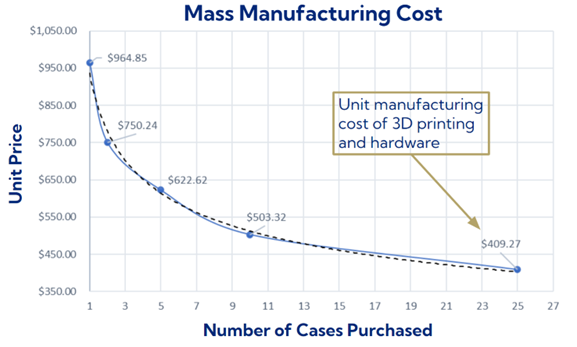

Conducted manufacturing feasibility study and plan for quick deployment

Our project won first place in Georgia Tech's Mechanical Engineering Summer Capstone Exposition